Boolean Systems for Digital Fabrication

Team:

Solo

Role:

Digital Fabrication, Laser Cutting, 3-D Modelling

Duration:

3 weeks

Software:

Rhino, Adobe Illustrator

Objective

Inspiration

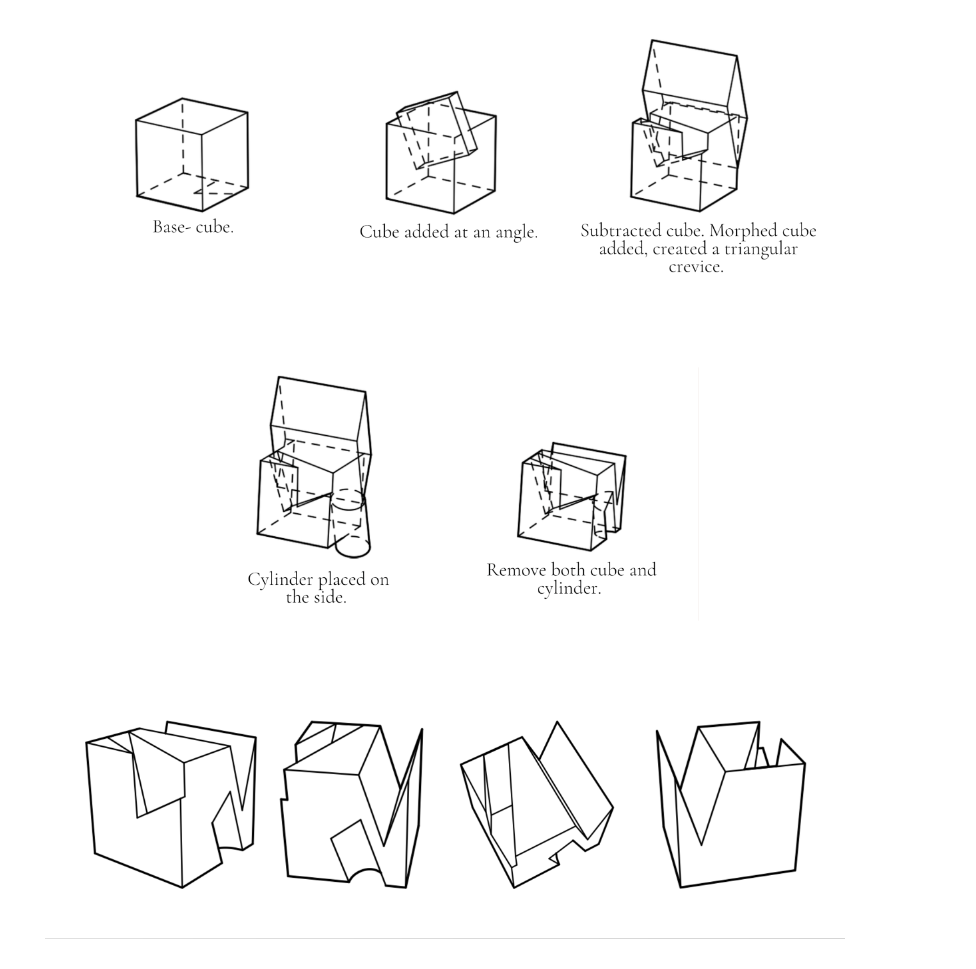

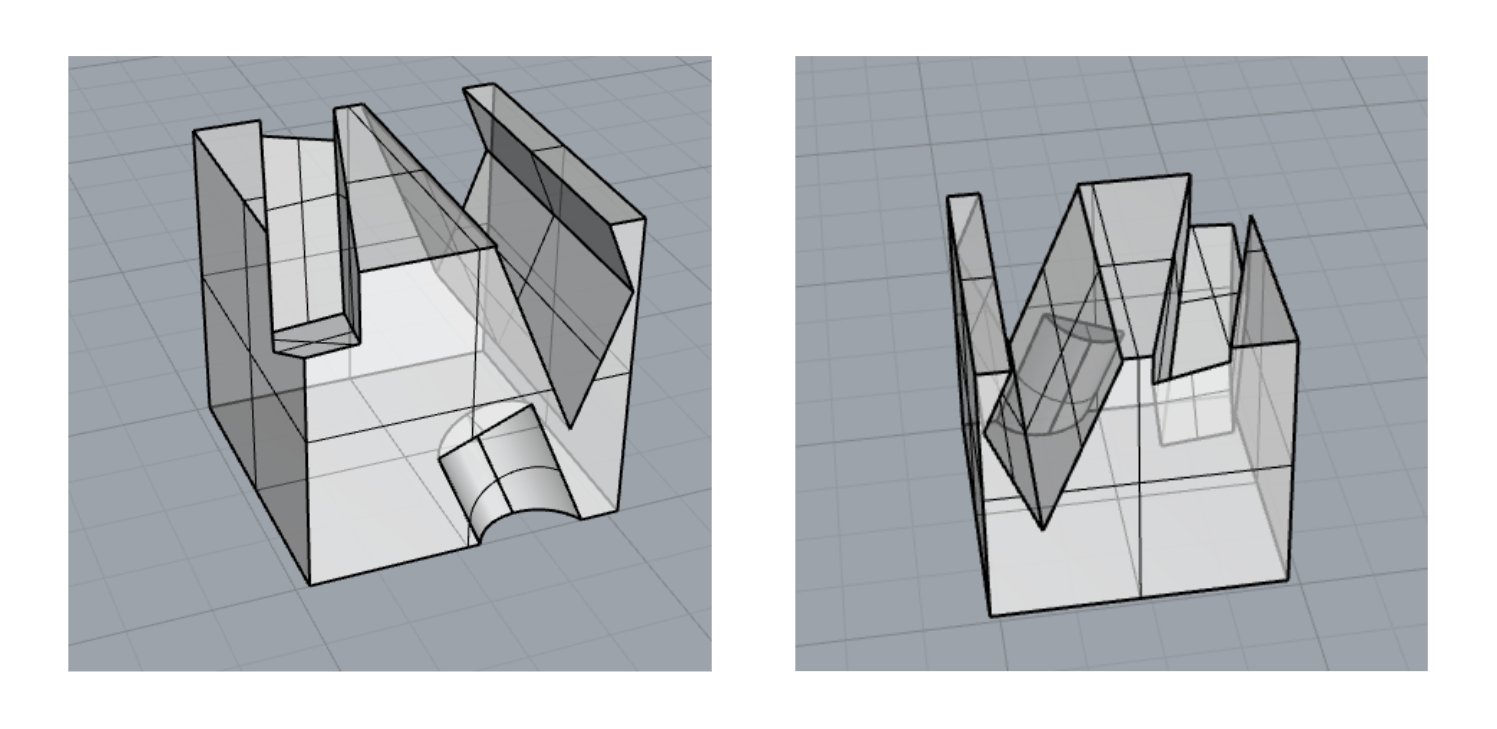

Design Development

Design Development

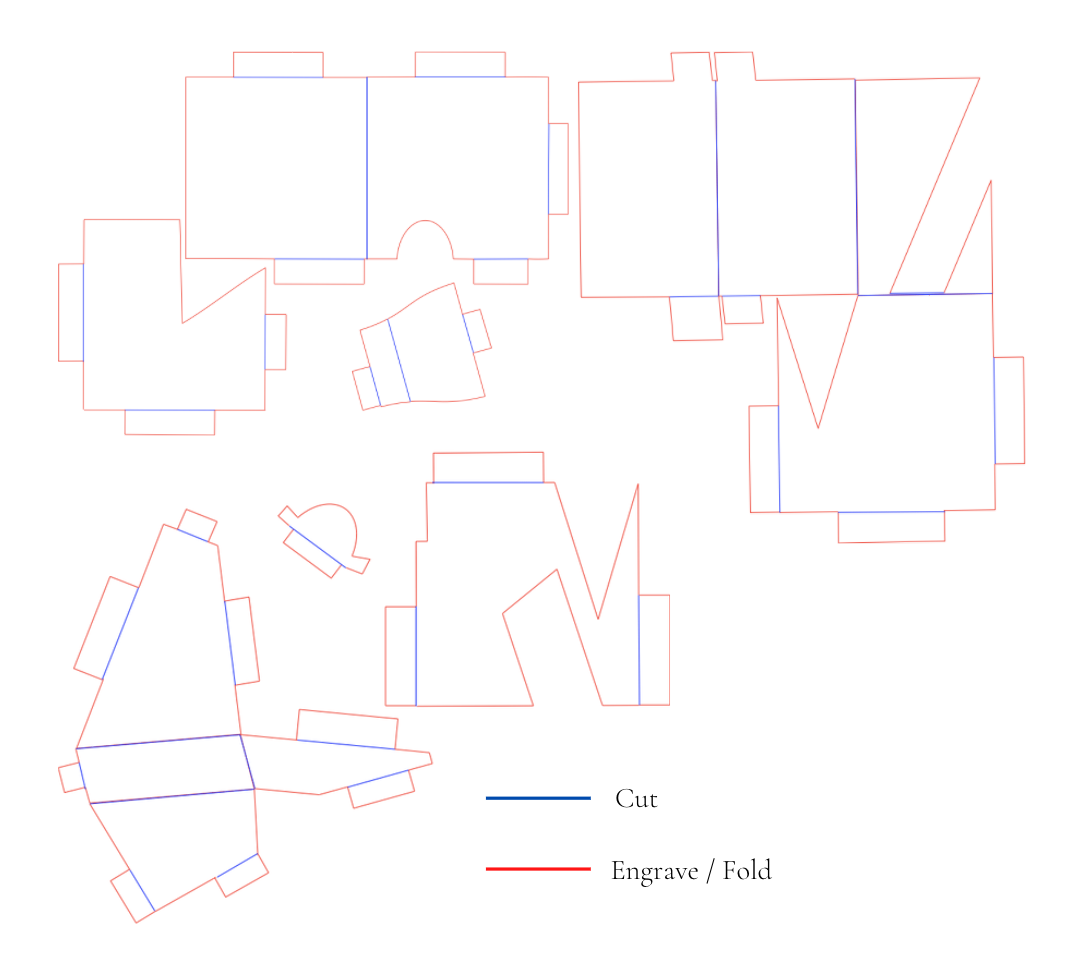

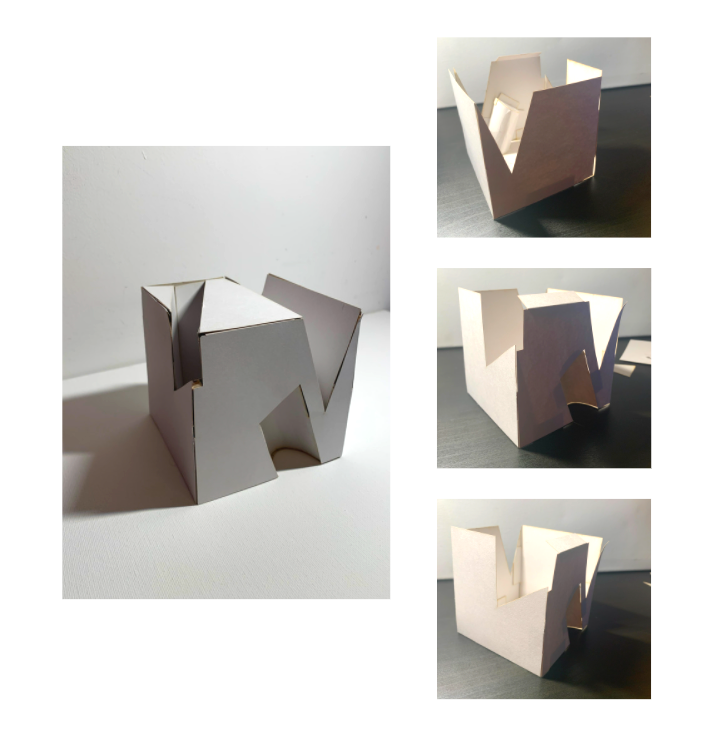

Laser cut 2D to 3D

All Models

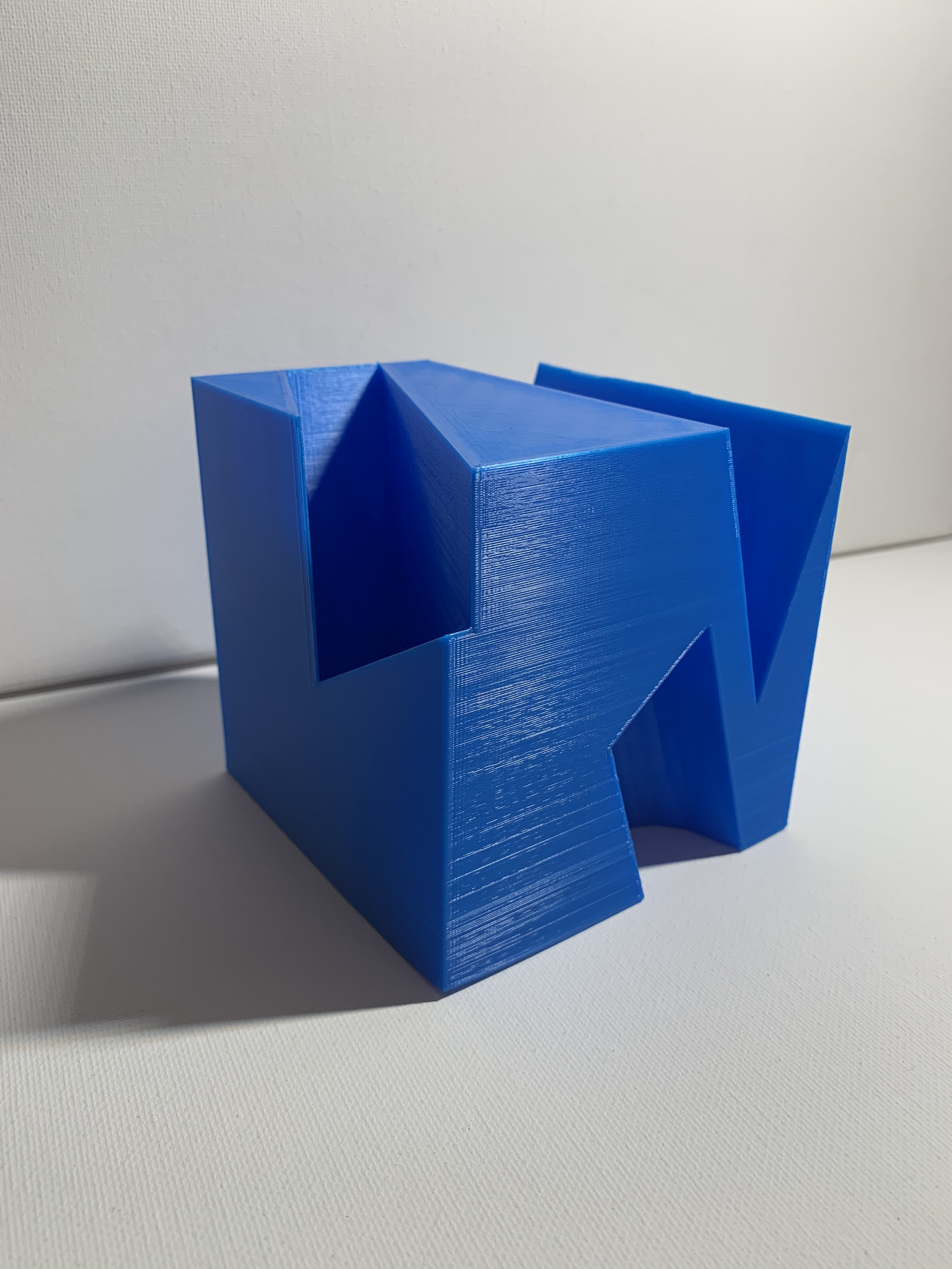

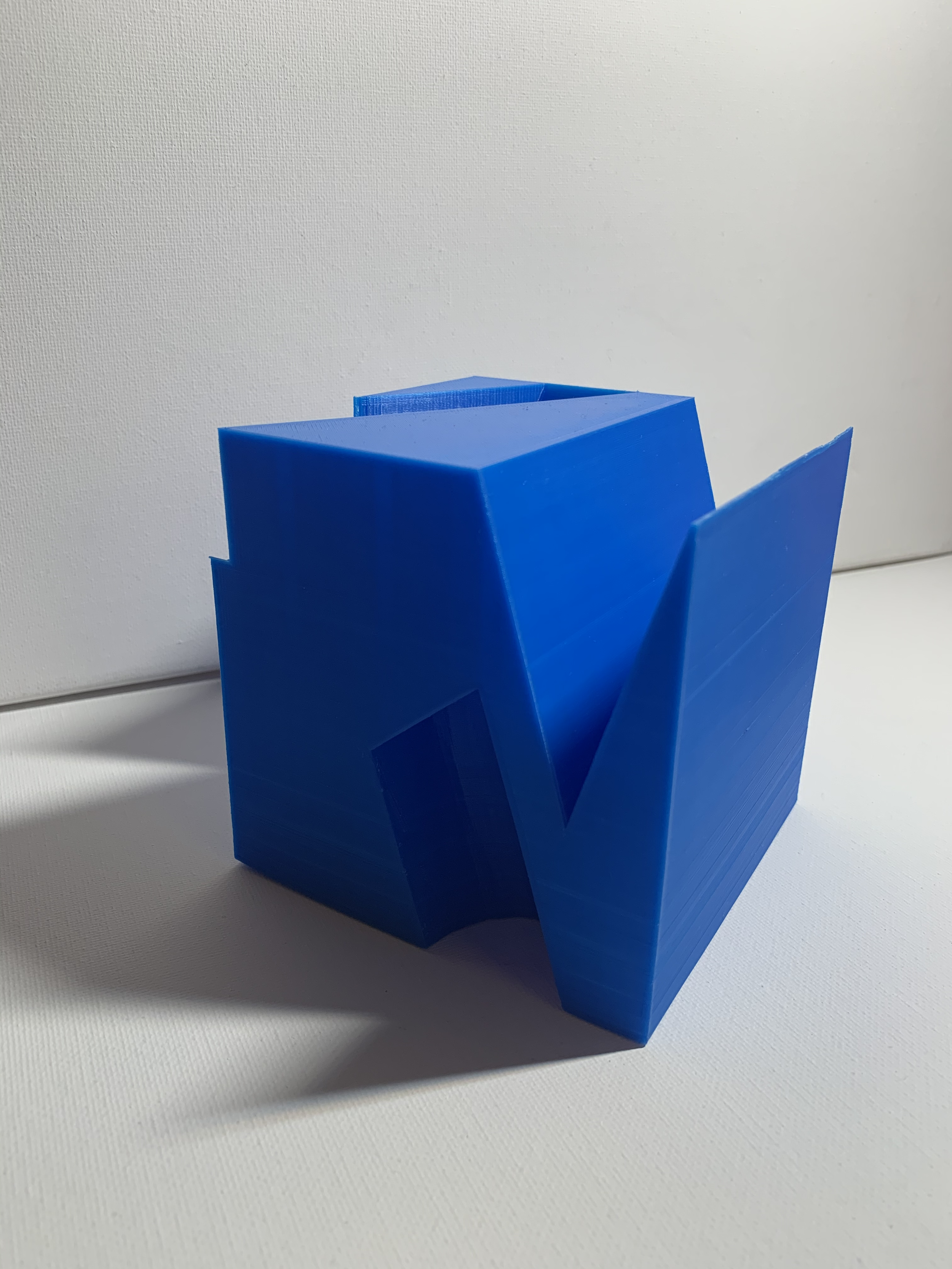

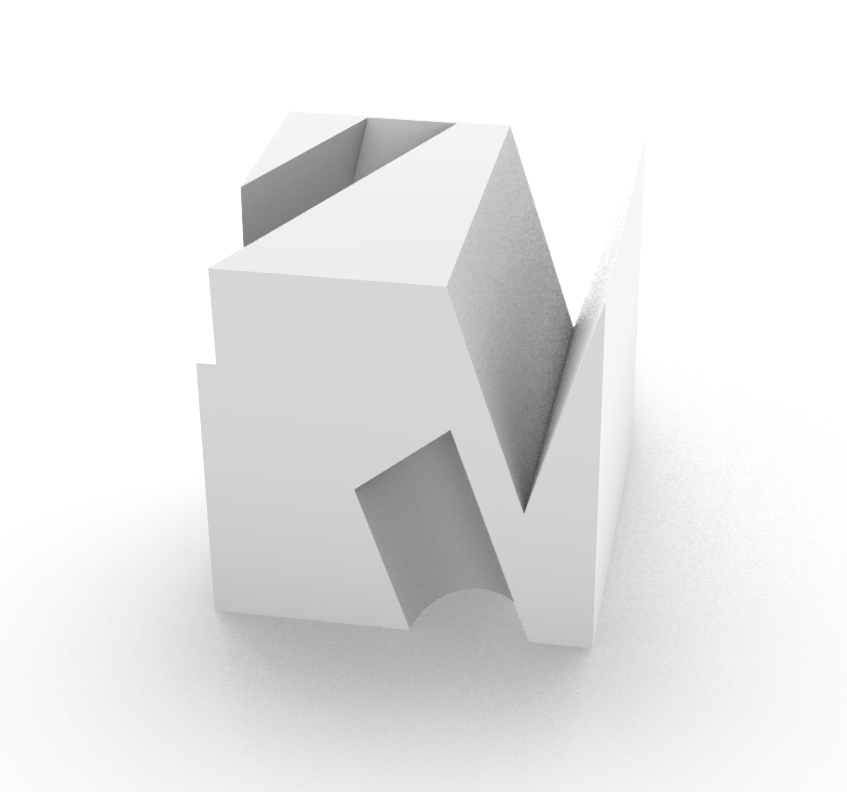

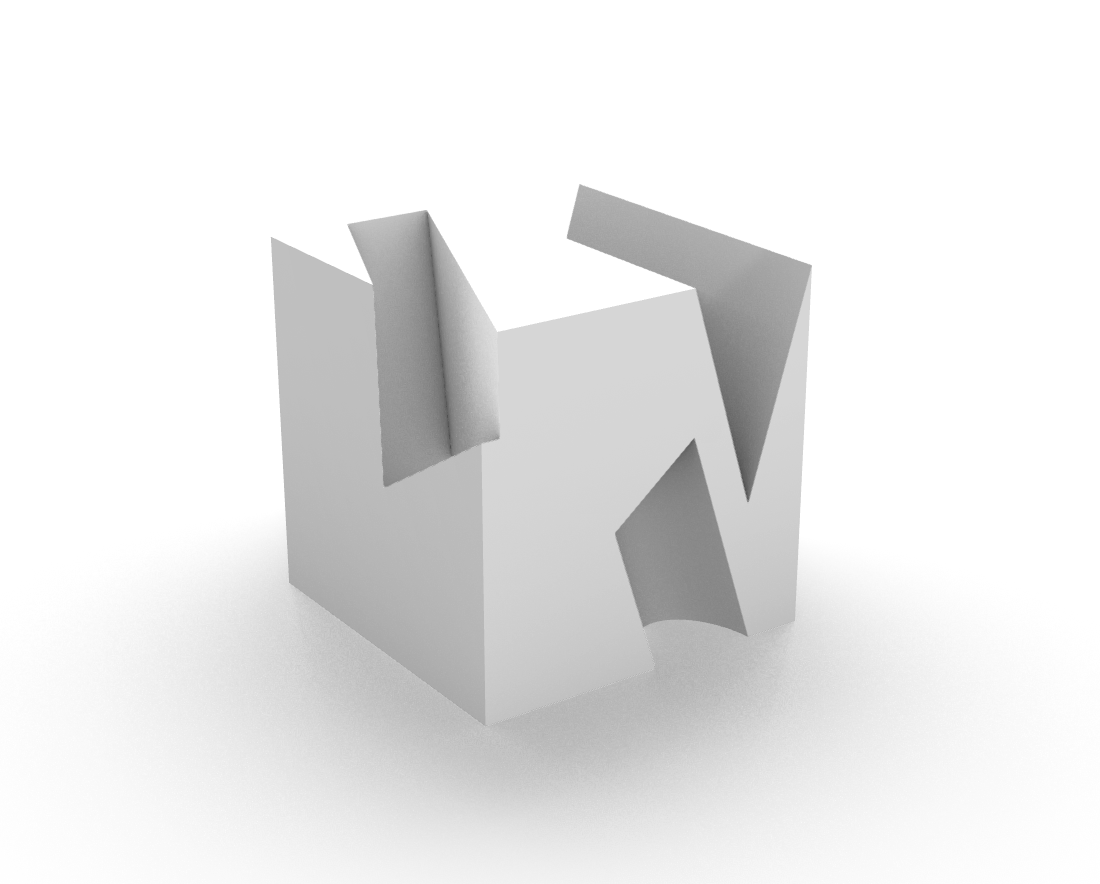

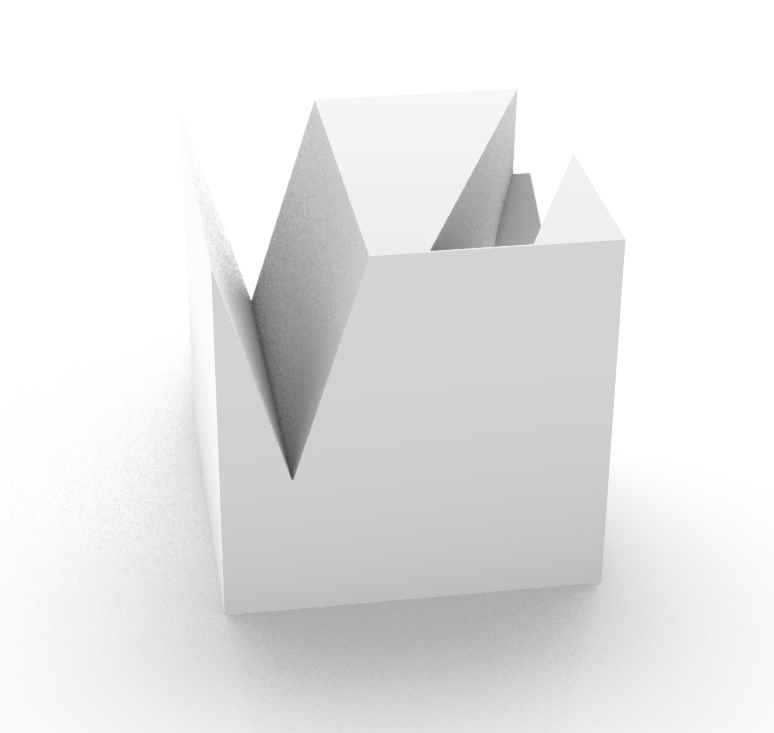

Use boolean systems to develop a 3D model (.3dm and .stl), produce a 3D-printed digitally fabricated artifact (PLA), and create 2D line drawings for laser cutting that transforms into a 3D physical artifact (card stock) through folding (tabs, adhesive, score, etc.)

I was inspired by the juxtaposition and relationship of geometric lines. I was also inspired by functionalism as I wanted to create an object that would potentially hold things.

What I learned

Being a novice to the world of 3D printing, as well as my first time using the software required for the project, the overall experience has been extremely informative and rewarding. I learned incredibly through the detailed digital fabrication process and am thankful for this experience.

Weaknesses/ opportunities to improve

Looking back, I see that there are many things I would improve.

Starting with the design of the model itself, I would make some adjustments to the overall design. I had a hard time visualizing and understanding the proportions from the software to real life but having gone through the process, I have a much clearer understanding now.

My goal was to make the object functional in some manner and for it to be able to hold things. I think I achieved that, but there are some details I would improve- such as shortening one of the edges.

Having completed this process, in the future, I will be better apt to understand how the various processes collide and work in conjunction.

Overall, this project was extremely helpful in providing the tools and resources to provide the basics of digital fabrication.